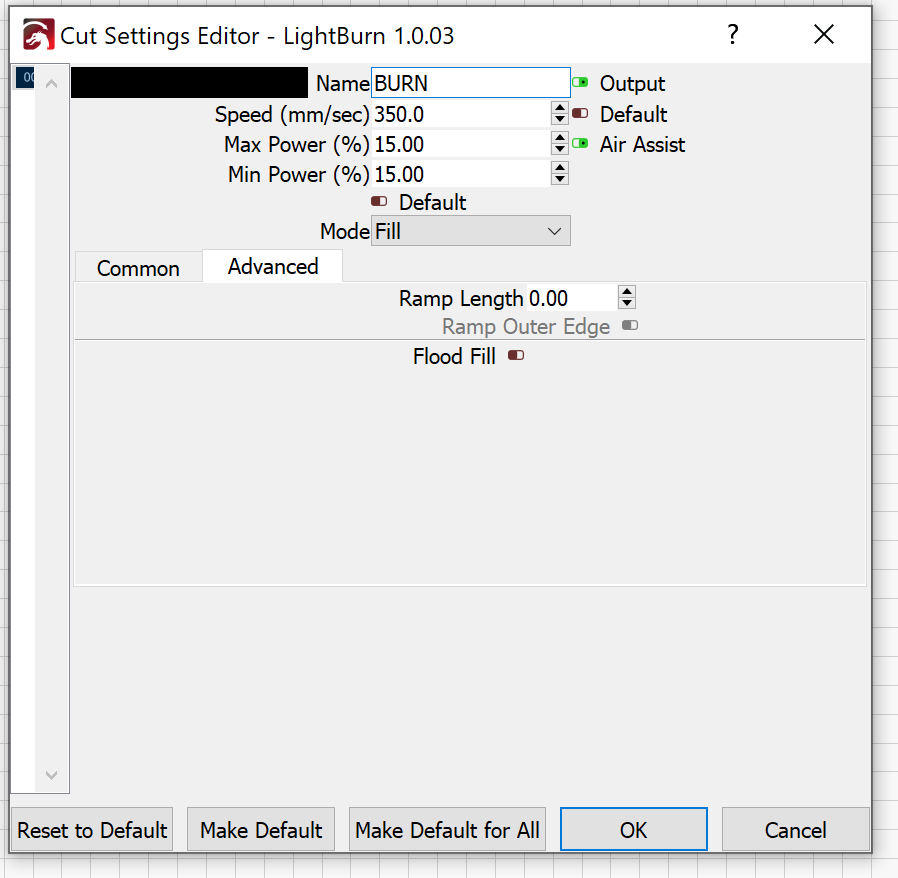

If you want to do surface marking, an 8-bit controller running Grbl 1.1f would be a better choice, and if you want to go fast, a Smoothieboard running Grbl-LPC is hard to beat.

If you were using a diode where speed isn’t high anyway, or you primarily want cutting or vector scanning, you’ll get by with the ramps combo. Filled vectors work well because the gcode isn’t very heavy, but for images, where the dot density is really high, you end up with 3 or 4 gcode instructions per dot, roughly, and the throughput of the controller and the serial connection will limit you. The 2nd and 3rd points limit the complexity of code that can be processed. This isn’t an issue if you’re cutting or doing filled engraving where the system can use overscan and ramp up to speed outside of the cut. The first one means that vector marking (getting a consistent line on a surface) is tricky because as the controller slows for corners it doesn’t lower the power, so you get dark spots at start / end points and sharp points in your shapes. No ramping of power output based on velocity of the laser head.Marlin isn’t terribly well suited for laser work for a couple reasons:

0 kommentar(er)

0 kommentar(er)